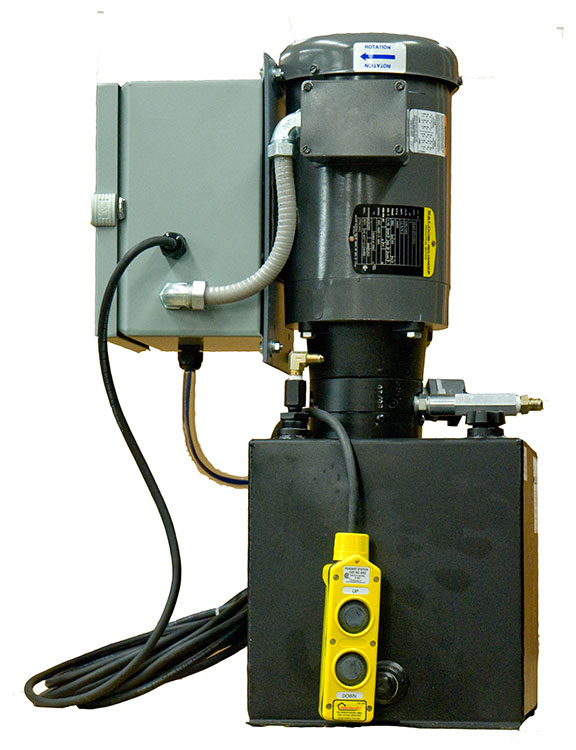

Self-Contained Power Unit

All components which comprise the power unit are situated beneath the platform, freeing up space on the floor.

Central Lubrication System

Used in conjunction with high cycle package. Provides continuous lubrication to all pivot points. Useful in applications where unit cycling is high.

Remote Manifold for Central Lubrication System

Remote Manifold for Central Lubrication System to make lubrication easier.

High Cycle Package

High cycle bearings are provided at pivot and roller points. Utilized in applications of high cycle frequency

Gravity Conveyor or Chain Driven Conveyor

Available in many sizes and capacities to assist in moving product on lift table platform.

Manually Operated Stop For Rotating Platform

A metal shaft locks the rotating platform in 90 degree increments.

Rotator ONLY.

Rotating Top Brake

This option stops the rotating platform at any position.

Rotator ONLY.

Spring Loaded Rotator Stop for Rotating Platform

A positive spring and lever detent which can be disengaged – Rotator will lock every 90 degrees.

Rotator ONLY.

Spring Activated Detent Stops for Rotating Platform

Comes with spring mechanism, which automatically slips into position every 90 degrees to stop platform rotation. Rotator ONLY.

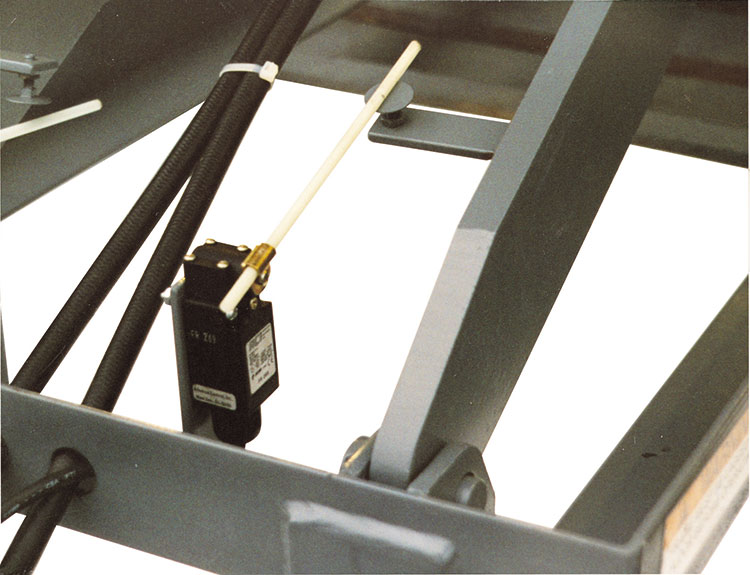

Home Position Limit Switch for Rotating Platform

A limit switch that provides an electrical signal when the rotating platform is moved to the “home” position. Note: Shown with rotating top removed for clarity..

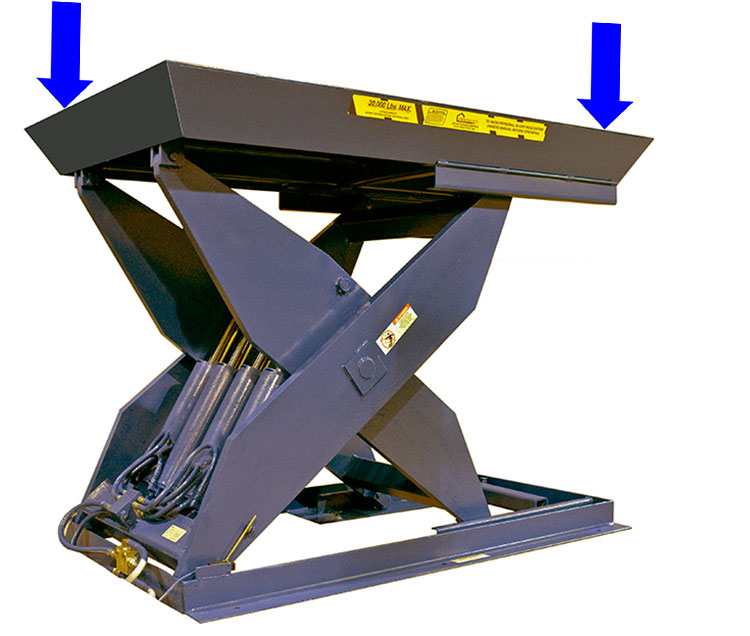

Beveled Toe Guards

Tapered toe guards are provided at the sides of the lift platform. The toe guards act as a wedge to push objects away from the lowering path of the lift platform edges.

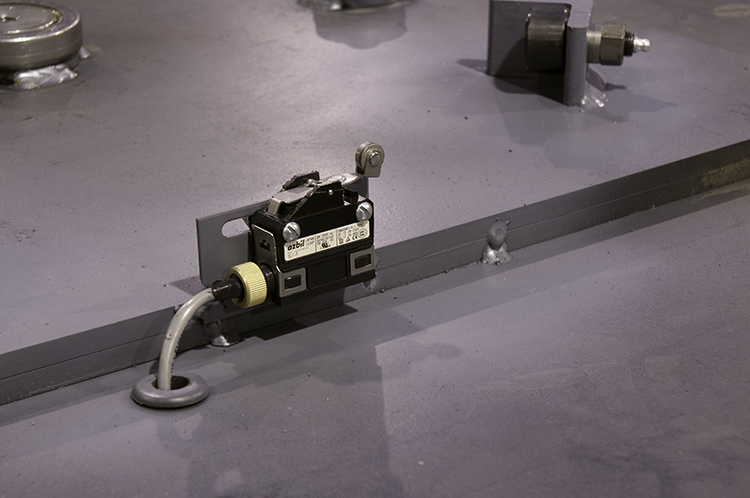

Up Travel Limit Switch (Factory Installed)

This option utilizes a limit switch that stops the unit’s upward travel at a preset travel dimension every time.

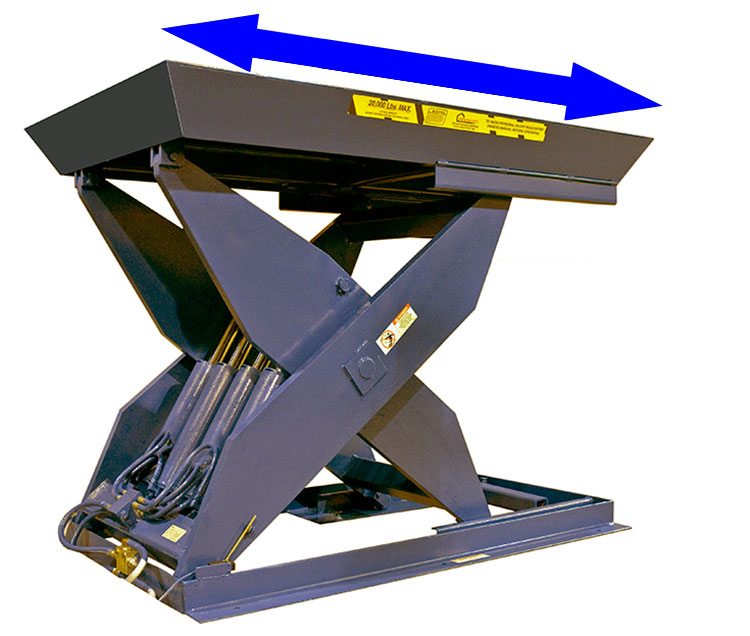

Non-Standard Platform Width

Custom width platform - built to specific application requirements.

Non-Standard Platform Size

Lift table platform sizes of a special length and / or width.

Accordion Bellows

Reinforced yellow vinyl bellows with pleats and reinforced rods help to prevent debris from entering the underside of the lift.

Locate / Hold Pins

Synchronization of multiple lift tables

Using specialized electro hydraulic technology multiple lift tables are synchronized to raise and lower in unison.

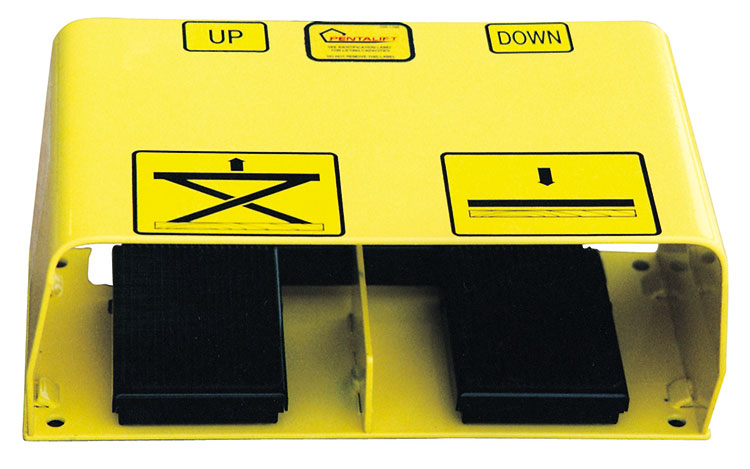

Guarded Foot Pedal Control Station

Offers control of the raising and lowering of the lift via foot pedals.

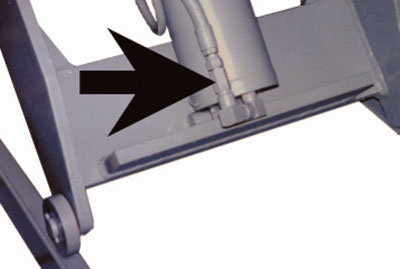

Hydraulic Velocity Fuse

Prevents free-fall if the hydraulic hose is severed. Note: The fuse may not lock if the lift table load is light in relation to its overall capacity.

Controls – Push button on post on platform

A post with the control push button on top of it is provided on the platform of the dock lift. This option is utilized on dock lifts on which a fork lift will be driving on and being raised or lowered.

Controls – Removable push button on post on platform

A post with the control push button on top of it on removable cord is provided on the platform of the dock lift. This option is utilized on dock lifts on which a fork lift will be driving on and being raised or lowered.

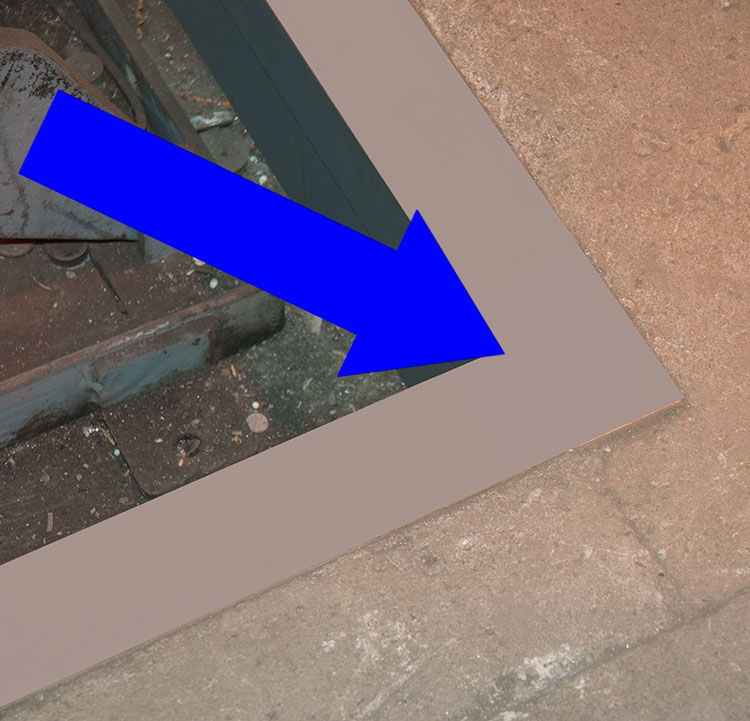

Pit Curb Angle

Steel angle iron with tab anchors welded along it are provided and embed into the edges of the dock lift pit. The curb angle provides a metal edge protects the pit edges from breaking away during fork lift roller overr.

Toe Sensor

A bar that is electrically interlocked, surrounds the lower perimeter of the lift's platform and electo/hydraulically arrests the downward decent of the lift when an obstruction is encountered.

Hydraulic Dock Lift Bridge Assist

This hydraulic bridge assist is installed on the top platform surface of the lip. It improves safety, ergonomics and efficiency in positioning bridges or lips of this heavy nature.

Hydraulic power unit horsepower

For any given lift, increasing the horsepower rating of the power unit increases the lifting travel speed of the lift.

Hydraulic power unit voltage

The power supply voltages available include 115 and 220 volt single phase. 230, 460 and 600 volt 3 phase. 380 3 phase 50 hertz voltage is also available. 3 phase voltages are recommended where possible to avoid any line loss issues.

Lowered height

Low height refers to the dimension from the bottom of the frame to the top of the platform when the lift table is in the fully lowered position.

Capacity End / Side Edge Load

Capacity End / Side Axle load

The maximum amount of single axle load (in the case of rolling loads) which can be applied to the loading edge of the platform (end or side) when the lift is in any raised position.

Capacity

The maximum load (evenly distributed) that the scissor lift can accomodate and lift.

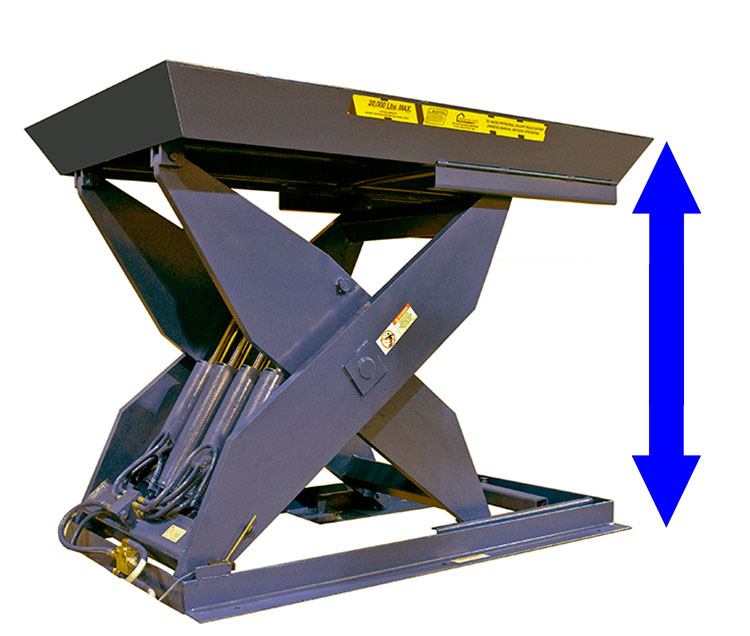

Vertical travel

The difference between the fully raised height of the lift deck and the fully lowered height of the lift .