As dock and warehouse safety issues grow in importance along with productivity and environmental mandates, there becomes an increasing need for more innovative equipment. One of the areas of ongoing innovation pertains to levelers. There are three basic types of dock levelers: mechanical, air and hydraulic units. The type you will want to use will depend on the application. Here is a closer look at the different levelers:

As dock and warehouse safety issues grow in importance along with productivity and environmental mandates, there becomes an increasing need for more innovative equipment. One of the areas of ongoing innovation pertains to levelers. There are three basic types of dock levelers: mechanical, air and hydraulic units. The type you will want to use will depend on the application. Here is a closer look at the different levelers:

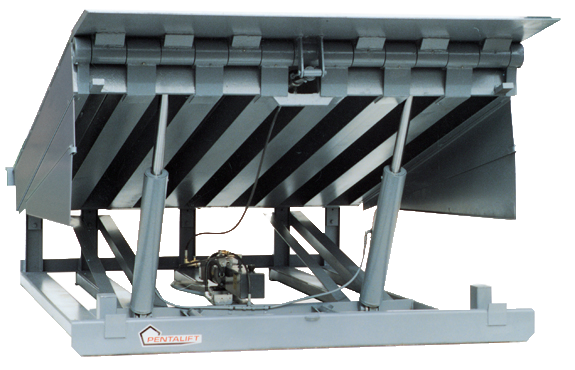

Hydraulic levelers

Designed for high capacity, hydraulic dock levelers make the loading and unloading of products at the loading dock an easier process then mechanical.

Mechanical levelers

Mechanical dock levelers are easy to operate, durable, reliable and incur zero energy costs. If at a later date you want to turn your mechanical leveler into a hydraulic leveler, Pentalift can retrofit the leveler with a hydraulic conversion kit.

Air levelers

Air dock levelers are operated using an air-powered system. If you are considering an air powered dock leveler, you may want to opt for a hydraulic leveler instead, which is considered safer, has a less expensive installation process, is easier to clean and is available with more customization options.

Vertical dock levelers

This option is designed for cleanliness and temperature controlled environments and is activated hydraulically.

Roll Off Stop Lip dock levelers

Designed to stop the forklift drifting too close to the edge and falling off of the leveler.

Edge of dock levelers

Used in low capacity, low frequency settings, where a dock plate cannot offer the performance or ergonomics.

With so many different options, making the right selection can prove to be a daunting task. However, you will find that as you step back and assess your various requirements, the most appropriate choice will become more evident.

Here are a few criteria that you will want to take into account:

Your specific needs

Each operation will place different demands on a dock leveler. It is essential to make sure you pick the right leveler for your individual requirements. You’ll need to take into account the type of vehicles that will use your dock or the type of loading bay. Things to consider are frequency of use and load capacities and trailer dimensions.

Safety first

Health and safety is for most organizations a top priority, and you’ll need to be aware of safety when selecting dock levelers. The leveler covers the gap between the dock and trailer that is crossed by forklifts many times each year. Ensure the leveler you choose covers safety in four key areas: vacant dock drop-off protection, free-fall protection, protecting cross traffic against gaps in the floor, and protection of personnel during routine leveler maintenance.

Maintenance costs

There is more to consider than just the initial cost of the leveler you choose. Maintenance costs should also be considered. Try to ascertain the availability of spares and look for an uncomplicated design. Above all check the quality of construction. Not all levelers are equal and quality varies widely.

Reliability and durability

It is important to get maximum reliability from your dock leveler. Therefore you should consider your individual application to ensure the equipment you finally choose meets the challenge. At first glance structural differences between models may not be obvious. Therefore when evaluating equipment, you should look closely for stability, strength, design and quality of construction.

Support and after sales

Manufacturer support and after sales service is an important consideration when choosing a dock leveler. This is a long term investment and a dock leveler is an important part of your operation. You’ll need a manufacturer who stands behind the equipment they sell. They should offer after sales service.

Following these simple steps will go a long way in helping you choose the right leveler for your business application. Pentalift can help you decide which type of leveler is best for your operation, or create a custom solution that meets your unique needs. Contact us today at 519-763-6700 to learn more about our dock levelers.