Electrical Options – Overhead Door kit

A limit switch and a mechanism for activating the limit switch by the overhead door is provided. This interlock prevents the dock lift from being activated unless the door is in a sufficiently raised position.

Bottom Curtain

The bottom curtain is attached to the underside of the vertical dock leveler. When the vertical dock leveler is lowered to load or unload the truck the curtain

Continuous Pit Installation

A series of vertical storing dock levelers are installed on a continuous ledge. The main advantage of this type of installation is easier cleaning.

Individual Pit Installation

The vertical storing dock leveler is installed into a three sided pit. The advantage of this installation style is that the dock floor surface extends

Foam Insulation

Hot Dip Galvanizing – Things to know

Hot dipped galvanizing is a coating that is applied to metal to provide unmatched corrosion protection and resistance. Hot dip galvanizing is well suited to vertical storing dock levelers that will be utilized in wash down applications.

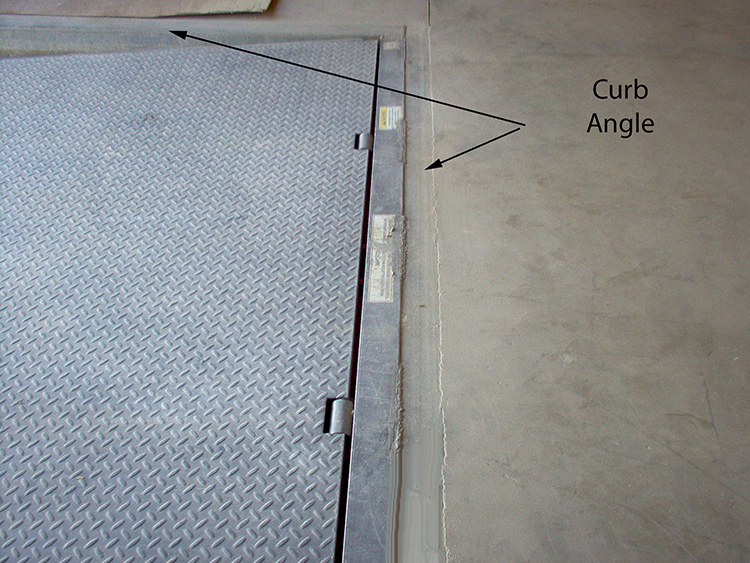

Curb Angle Assembly

Steel angle iron with tab anchors welded along it are provided and embed into the edges of the dock leveler pit. The curb angle provides a metal edge to weld the dock leveler to during installation...

Lip Length

There are three standard lengths of air/hydraulic powered dock leveler lips, 16”, 18", and 20". Â The length of dock leveler lip required depends on various factors including but not limited to:

Tapered Lip

Lip Hinge Grease Fittings

Lip hinge grease fittings facilitate the application of grease to the dock leveler lip hinge.

Vehicle Restraint Interlock

A combination control panel is provided and operates the Air/hydraulic dock leveler and the vehicle restraint from a single panel. The hydraulic dock leveler is interlocked to the vehicle restraint. The air/hydraulic dock leveler cannot operate until the truck / trailer has been properly engaged by the vehicle restraint.

Power Supply Voltages

The power supply voltages available include 115 and 220 volt single phase. 380 3 phase 50 hertz voltage is also available. 3 phase voltages are recommended where possible to avoid any line loss issues.

Control and Power Unit Stanchion

Control and power unit stanchion provides the ideal means to install and locate the electrical control panel and the hydraulic power unit(s) in applications where access to the interior wall adjacent to the dock leveler is impaired.

Dock Leveler Length

Dock levelers are available in 6 and 8 ft lengths. Longer lengths are utilized when the difference in height between the loading dock floor and the truck to be serviced increases.

Dock Leveler Width

Dock levelers are typically available in 6, 6.5 and 7 ft wide (nominal) sizing. The width of the dock leveler is dependent on the width of trucks being loaded / unloaded and configuration of loads.

Dock Leveler Capacity – Understanding Loading Dock Capacity

Capacity is one of the most critical specifications to determine when selecting the dock leveler. It is extremely important to fully consider and properly