This page explains options that are common to Pentalift loading dock seals. For more information on any of these options or Pentalift products, contact your Pentalift representative.

Door Number Sewn on Curtain

Include fabric cut-outs sewn into the curtain to clearly mark door numbers.

Wear Pleats

Provide additional dock seal surface wear protection as truck moves up and down on its suspension during loading / unloading.

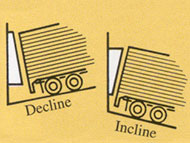

Tapered Side Pads

Compensates for and provides the best seal on declined or inclined approaches

Head Pad Drop Curtain

To accommodate applications where the door height is higher than the top of the truck heights.

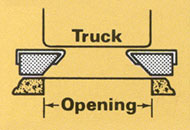

Beveled Side Pad

Beveled side pads seal the truck in an application with wider building doors.

RS800 RainStop Seal

Prevents rain from running off the top of a trailer into the dock area.