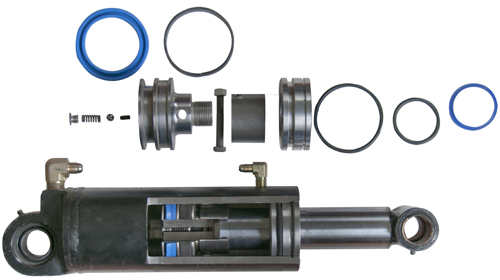

The lift cylinder is the heart of any hydraulic lift system. Pentalift’s exclusive design ensures the longest cylinder life, reduces maintenance and eliminates oil spills.

How it Works

Pentalift’s PentaFlow cylinder is completely sealed from the surrounding atmosphere and all components are continuously bathed in fresh oil. Contamination and deterioration of the cylinder cannot occur. When the cylinder reached full extension, the bypass valve opens and allows oil to flow through the piston to the rod side of the cylinder, out the port and back to the reservoir. This prevents the cylinder from dead ending and building high stresses in the cylinder, equipment structure, and hydraulic system. Air in the cylinder is automatically ejected through the bypass valve. The need for manual bleeding which often results in oil spills is eliminated.

The lower pivot is a spherical bearing. The spherical bearing accommodates high cycle use as well as compensating for any minor misalignment that might occur. A grease fitting is provided for the spherical bearing to facilitate easy lubrication.

The cylinder barrel is manufactured from precision DOM (Drawn Over Mandrel) tubing. The inside wall of the barrel is precision honed for a reliable seal and maximum life for Hydraulic seal.

The bypass cartridge piston is precision machined. It houses the bypass cartridge components. The bypass chamber is precision machined to tight tolerances for long term reliability. The bypass cartridge piston also carriers the wear ring and “U” cup piston seal.

The wear ring guides the piston as it strokes back and forth in the cylinder. The wear ring material polishes the honed cylinder wall, maintaining the smoothes and consistency for long term reliability.

The polyurethane “U” cup seal is high cycle designed. It maintains a reliable seal for a long reliable function of the cylinder and the lift.

Bypass components: The drilled set screw, spring, ball, through bolt and dump tube all function as an assembly to facilitate the “bypass” feature. As explained above, the bypass feature is extremely beneficial for lift applications. The simplicity of components and precision machining ensure long term reliable function.

The aluminum head nut is precision machined. It houses high cycle hydraulic seals on its inside and outside diameters. It is the cap that holds the cylinder together.

The cylinder rod is manufactured from high strength steel. The rod is machined and ground for precise dimensioning. It is then hard chromed for maximum cylinder life.

The components and construction of the PentaFlow cylinder are so superior that in extremely high cycle applications, in which other lift table components are upsized and high cycle bearings implemented at lift pivot points, the PentaFlow bypass cylinder remains unchanged. In these applications it functions reliably for the life of the product.

Our Primary Goal is to engineer and build the best lift table products to ensure the ultimate in user safety and product reliability. Please Contact a Pentalift sales representative to discuss your application requirements.