Scissor lifts are one of the most often used products in any manufacturing or material handling facility. Making them more efficient is what Pentalift does best. We’ve always offered options which improve the efficiency of lift tables, suiting almost any application, and now we’ve included that list to our website.

With over fifty common options featured with descriptions and product specific applications, the job of the industrial or mechanical engineer – deciding on what lift table options best suit their specific application – becomes simplified, while the health and safety manager is encouraged by the additional ergonomic value the options introduce; increasing employee moral through better working conditions, placing less strain on the operator’s bodies.

Everyone wins when additional options are included into a scissor lift order. Through the improved working conditions we see increases in efficiency and decreases in disability claims.

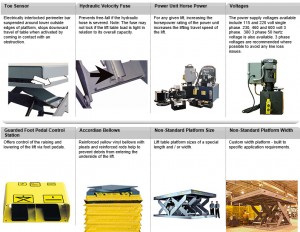

Examples of these beneficial options include accordion bellows, which keep debris away from the lift table’s mechanical parts, while a rotating platform top offers the operator a more convenient and efficient way to handle materials; increasing work flow through ergonomics.

When the manufacturing floor is one of the major settings for accidents and employee fatigue, it makes fiscal sense to include as many ergonomic options as possible per product purchase.

To see the complete line of common scissor lift table options, please visit Pentalift.com